Produktkategorier

Nyhedskategorier

SENESTE OPSLAG

-

Hvad er hovedkomponenterne i isfremstillingskondenseringsenheder?

Jan 09,2026 -

Hvordan håndterer man hurtigt kølemiddellækager eller isdannelse i et køleanlæg?

Dec 05,2025 -

Hvilke støj- og vibrationsproblemer genererer højeffektkompressorkondenseringsenheder?

Nov 28,2025 -

Hvad er de almindelige kølemetoder for kompressorkondenserende enheder?

Nov 21,2025 -

Er en luftkøler bedre end en AC?

Nov 14,2025

How to ensure that the Low Noise Evaporator Air Conditioner shell has high corrosion strength and impact resistance?

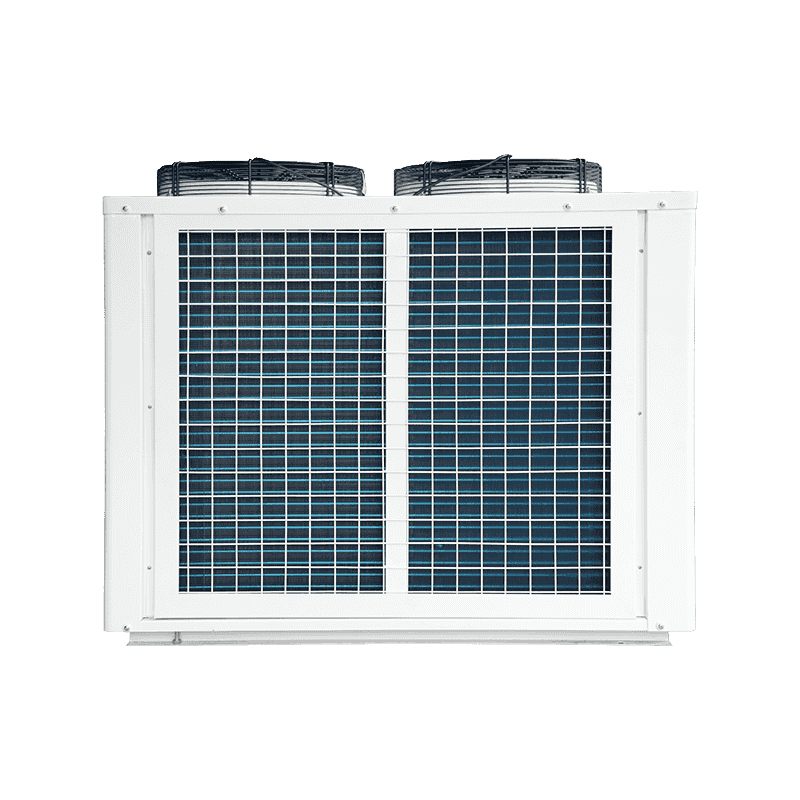

When designing and manufacturing the Low Noise Evaporator Air Conditioner, it is crucial to ensure that its shell has high corrosion strength and impact resistance. This is related to the service life of the product and directly affects its stability and reliability under various environmental conditions.

1. Select high-quality materials

The choice of shell material is the basis for determining its corrosion resistance and impact resistance. The shell of the Low Noise Evaporator Air Conditioner is made of white powder-coated aluminum. Aluminum itself has good corrosion resistance, and the white powder coating enhances its corrosion resistance. This coating can resist the erosion of various chemicals and environmental factors, ensuring that the shell will not rust or damage during long-term use.

2. High-quality coating process

The quality of the coating process directly affects the corrosion resistance and impact resistance of the shell. In the production process of the Low Noise Evaporator Air Conditioner, advanced powder coating technology is used to ensure that the coating is uniform, dense and has strong adhesion. This high-quality coating can prevent the penetration of moisture and chemicals, and can also maintain the integrity and stability of the shell when it is impacted by external forces.

3. Structural design optimization

The structural design of the shell is also an important factor in ensuring its high corrosion strength and impact resistance. The shell of the Low Noise Evaporator Air Conditioner has been carefully designed to have reasonable structural strength and rigidity. Through optimized design, the shell can disperse stress when impacted by external forces to avoid damage caused by local stress concentration. The edges and joints of the shell are also specially treated to ensure that no contaminated debris will be generated under various environmental conditions, thereby improving its corrosion resistance and impact resistance.

4. Strict quality control

During the production process, strict quality control of the Low Noise Evaporator Air Conditioner shell is also the key to ensuring its high corrosion strength and impact resistance. From the inspection of raw materials to the monitoring of the coating process to the inspection of the final product, every link is strictly carried out in accordance with the standards. Through strict quality control, it is ensured that every Low Noise Evaporator Air Conditioner shell shipped out of the factory has excellent corrosion resistance and impact resistance.

←

Hvorfor bruger Tecumseh -kompressorkondenseringsenheden LBP høj korrosionsmodstandspulverlakeret zink?

→

Why Does the High Power Industrial DD Air Cooler Have Significant Energy Efficiency Advantages?

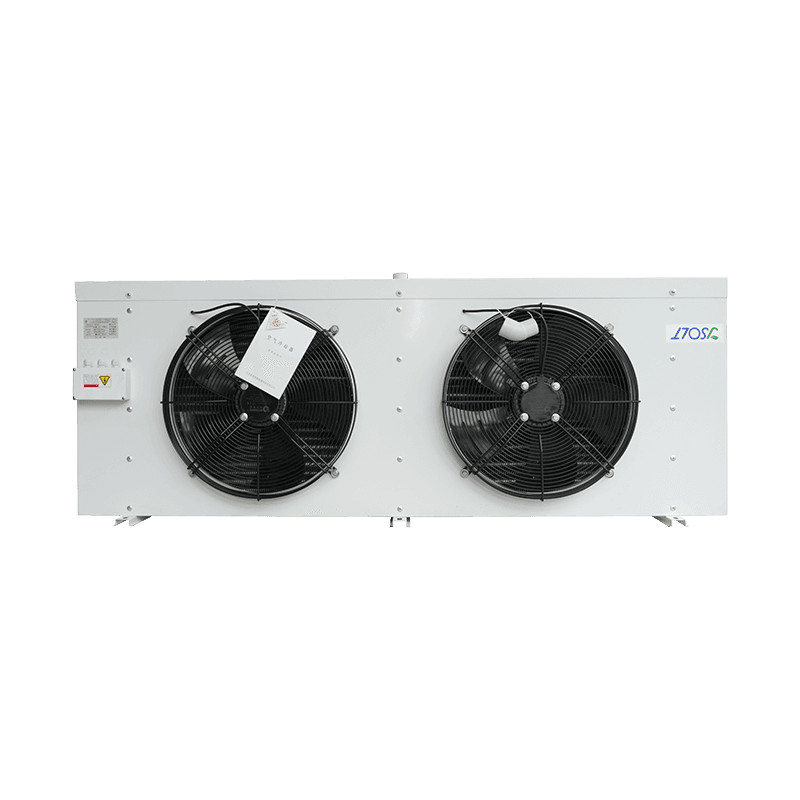

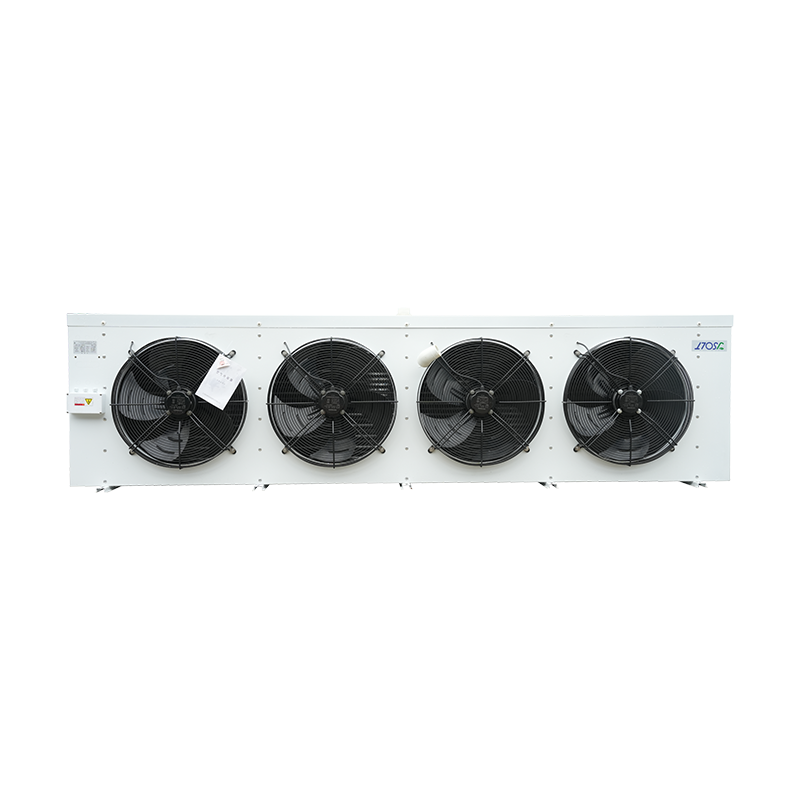

relaterede produkter

-

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province  +86-18082061600

+86-18082061600 / [email protected]

/ [email protected]

Copyright © 2024 Taizhou Best Refrigeration Equipment Manufacturing Co., Ltd All Rights Reserved. Producent af køleudstyr

DA

DA